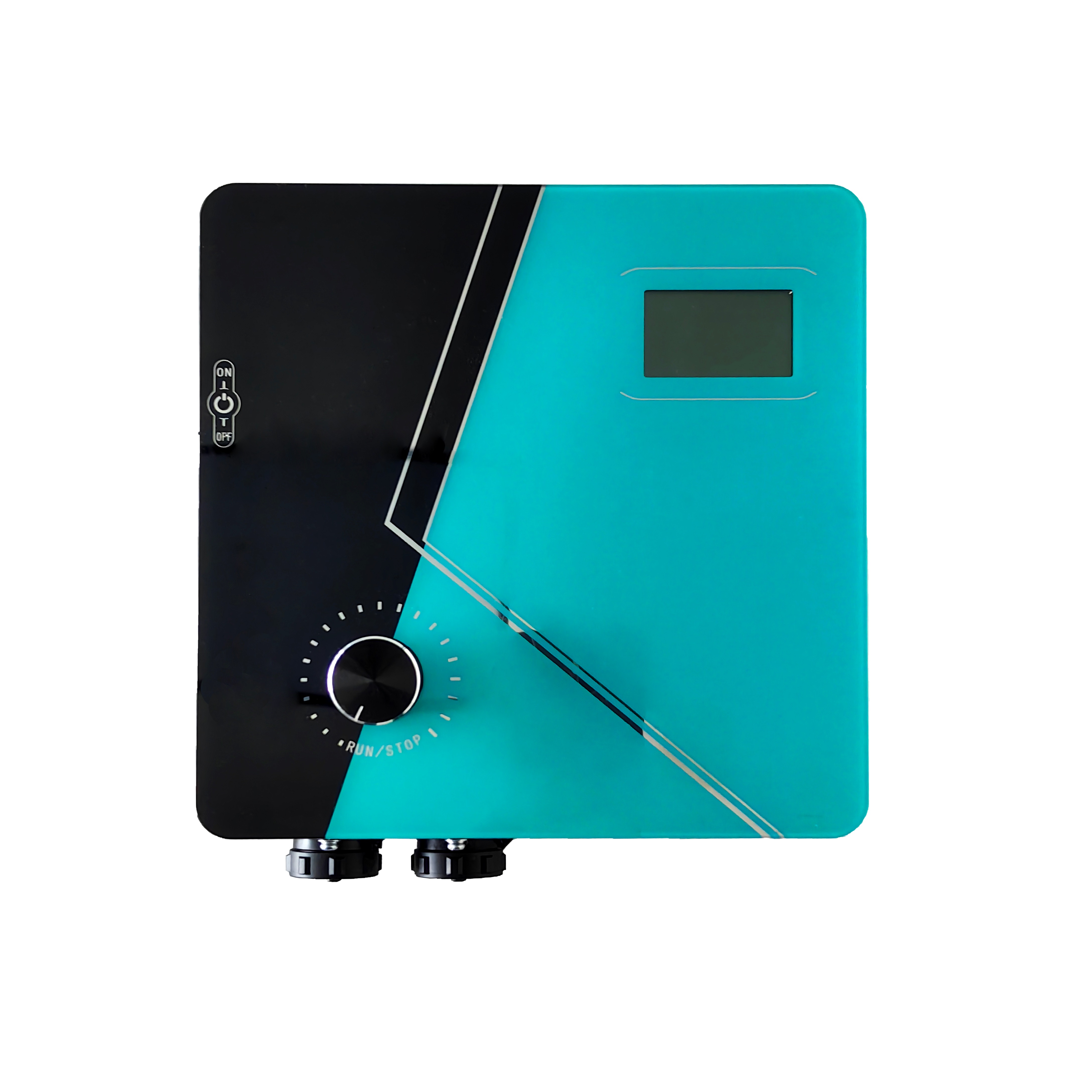

KD600 Series Vector inverter K-DRIVE

Product Features

- Optional STO (Safe Torque Off)function

- IGBT module for all models

- Redundant design of hardware solution ensures long-term stable operation

- The whole series is equipped with a metal backboard as standard, which provides stronger protection than the plastic backboard

- Extra large silicone buttons facilitate customer operation

- The whole series is equipped with a metal backboard as standard, which provides stronger protection than the plastic backboard

- Support LCD keypad, multi-language menu (optional)

- Detachable keyboard, external keyboard, convenient for customer debugging

- PC software, one-key setting,keypad parameter copy, saving customer debugging time

- Built-in EMC C3 filter, stronger anti-electromagnetic interference ability

- Independent air duct design prevents dust from contacting the circuit board, better heat dissipation performance

- Installation back mounting system can insert the inverter directly into the rack

- Programmable DI/DO/AI/AO

- MODBUS RS485, Profitnet, Profitbus, CANopen, Ethercat, PG, I/O expansion card

- Integrated PID function support most of water supply applications

- Integrated multi-speed function support maximum 16 speeds

- Support fire override mode

Technical Details

|

Input Voltage |

208~240V single phase & three phase |

|

380~480V three phase |

|

|

Output Frequency |

0~1200Hz V/F |

|

0~600HZ FVC |

|

|

Control Technology |

V/F , FVC,SVC, Torque Control |

|

Overload capability |

150%@rated current 60S |

|

180%@rated current 10S |

|

|

200%@rated current 1S |

|

|

Simple PLC support max 16-steps speed control |

|

|

Communication |

MODBUS RS485, Profitnet, Profitbus, CANopen, Ethercat, PG |

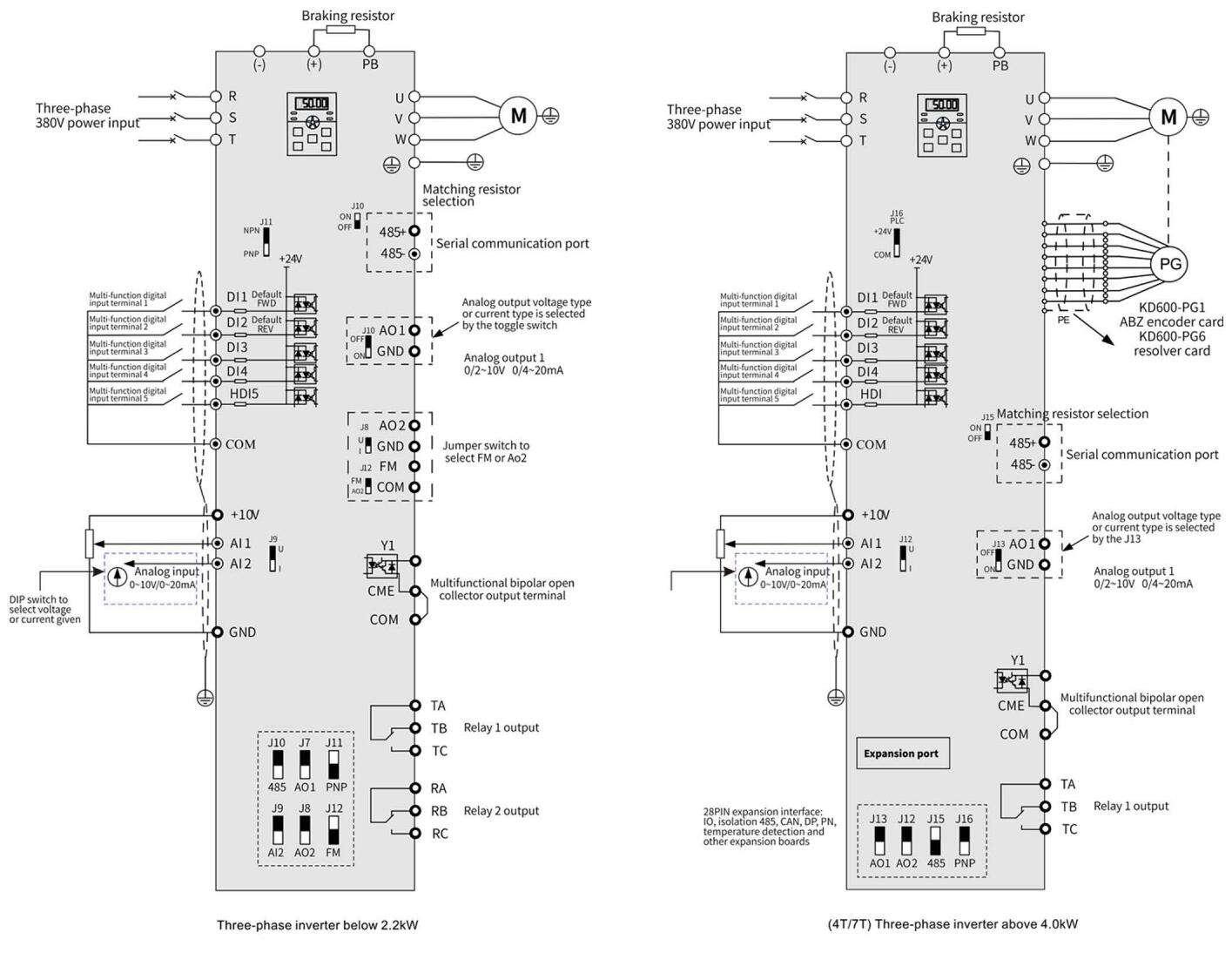

Basic Wiring Diagram

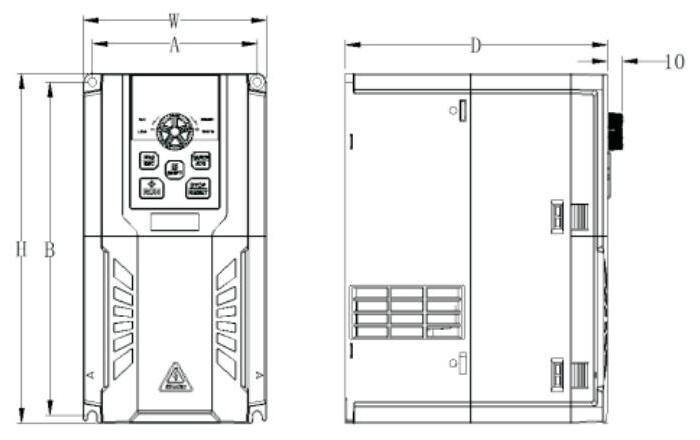

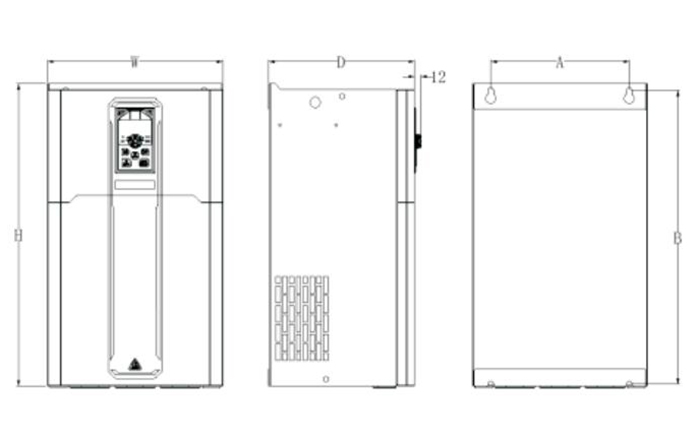

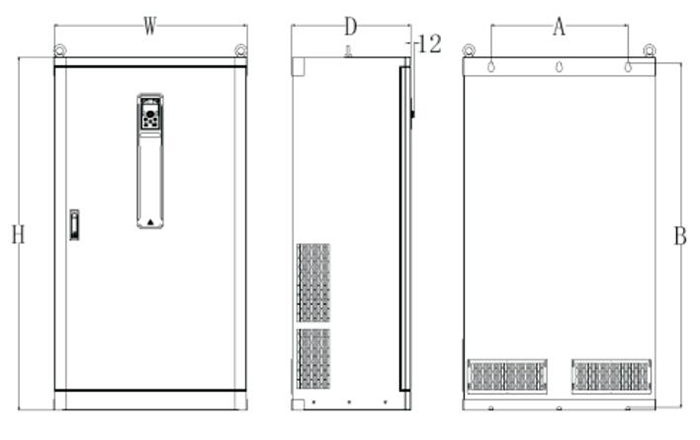

Model & Dimension

|

AC Drive Model |

Adapter motor (KW) |

Rated Input Current(A) |

Rated Output Current(A) |

Installation size(mm) |

Dimensions (mm) |

Aperture |

|||

|

A |

B |

H |

W |

D |

d |

||||

|

Input voltage:single-phase 220V Range:-15%~20% |

|||||||||

|

KD600-2S-0.4G |

0.4 |

5.4 |

2.3 |

76 |

156 |

165 |

86 |

140 |

5 |

|

KD600-2S-0.7G |

0.75 |

8.2 |

4.0 |

||||||

|

KD600-2S-1.5G |

1.5 |

14.0 |

7.0 |

||||||

|

Input voltage:three-phase 380V Range:-15%~20% |

|||||||||

|

KD600-4T-0.7G/1.5P |

0.7 |

3.4 |

2.1 |

76 |

156 |

165 |

86 |

140 |

5 |

|

KD600-4T-1.5G/2.2P |

1.5 |

5.0 |

3.8 |

||||||

|

KD600-4T-2.2G/4.0P |

2.2 |

5.8 |

5.1 |

||||||

|

KD600-4T-4.0G/5.5P |

4.0 |

10.5 |

9.0 |

98 |

182 |

192 |

110 |

165 |

5 |

|

KD600-4T-5.5G/7.5P |

5.5 |

14.6 |

13.0 |

||||||

|

KD600-4T-7.5G/9.0P |

7.5 |

20.5 |

17.0 |

111 |

223 |

234 |

123 |

176 |

6 |

|

KD600-4T-9.0G/11P |

9.0 |

22.0 |

20.0 |

||||||

|

KD600-4T-11G/15P |

11 |

26.0 |

25.0 |

147 |

264 |

275 |

160 |

186 |

6 |

|

KD600-4T-15G/18.5P |

15 |

35.0 |

32.0 |

||||||

|

KD600-4T-18.5G/22P |

18.5 |

38.5 |

37.0 |

174 |

319 |

330 |

189 |

186 |

6 |

|

KD600-4T-22G/30P |

22 |

46.5 |

45.0 |

||||||

|

KD600-4T-30G/37P |

30 |

62.0 |

60.0 |

200 |

410 |

425 |

255 |

206 |

7 |

|

KD600-4T-37G/45P |

37 |

76 |

75 |

||||||

|

KD600-4T-45G/55P |

45 |

92 |

91 |

245 |

518 |

534 |

310 |

258 |

10 |

|

KD600-4T-55G/75P |

55 |

113 |

110 |

||||||

|

KD600-4T-75G/90P |

75 |

157 |

152 |

290 |

544 |

560 |

350 |

268 |

10 |

|

KD600-4T-90G/110P |

90 |

180 |

176 |

||||||

|

KD600-4T-110G/132P |

110 |

214 |

210 |

320 |

678 |

695 |

410 |

295 |

10 |

|

KD600-4T-132G/160P |

132 |

256 |

253 |

||||||

|

KD600-4T-160G/185P |

160 |

307 |

304 |

380 |

1025 |

1050 |

480 |

330 |

10 |

|

KD600-4T-185G/200P |

185 |

345 |

340 |

||||||

|

KD600-4T-200G/220P |

200 |

385 |

380 |

||||||

|

KD600-4T-220G/250P |

220 |

430 |

426 |

500 |

1170 |

1200 |

590 |

365 |

14 |

|

KD600-4T-250G/280P |

250 |

468 |

465 |

||||||

|

KD600-4T-280G/315P |

280 |

525 |

520 |

||||||

|

KD600-4T-315G/350P |

315 |

590 |

585 |

500 |

1255 |

1290 |

700 |

400 |

16 |

|

KD600-4T-350G/400P |

350 |

665 |

650 |

||||||

|

KD600-4T-400G/450P |

400 |

785 |

725 |

||||||

|

KD600-4T-450G/500P |

450 |

883 |

820 |

/ |

/ |

1800 |

1000 |

500 |

/ |

|

KD600-4T-500G/550P |

500 |

920 |

900 |

||||||

|

KD600-4T-550G/630P |

550 |

1020 |

1000 |

||||||

|

KD600-4T-630G/710P |

630 |

1120 |

1100 |

||||||

|

KD600-4T-710G/800P |

710 |

1315 |

1250 |

/ |

/ |

2200 |

1200 |

600 |

/ |

Schematic diagram of plastic dimensions

and installation dimensions below 22KW

Schematic diagram of overall dimensions and installation

dimensions of 30 ~ 132KW sheet metal chassis

1 60KW Inverter Dimensions and Installation Dimensions

Case Study

OBTAIN SAMPLES

Effective, safe and reliable. Our equipment guarantees the right solution for any requirement. Benefit from our industry

expertise and generate added value - every day.

1.png)