Closed-Loop Stepper Driver

Product Features

- Itis compatible with pulse signal input and I/Ointernal control mode. One driveis with multiple functions bringing more expansion possibilities, greatly reducing system costs.

- With RS485 communication connection, based on standard ModbusRTU protocol,it can support multi-axis RS485 motion control network.

- There is an inherent resonance point in the stepping system. The C series of stepper drives adopts an excellent anti-resonance algorithm to capture the characteristics of the resonance point, which can effectively avoid or suppress the resonance point and improve the stability at medium andlow speeds and torque output at high speed.

- The built-in T-type and S-type command smoothing technology reduces the instantaneous disturbance caused by the load movement and transmission machinery so that it can make the motor movement more stable and smoothy.

- During the set acceleration time, the speed accelerates fr-om theinitial value to the set maximum value, and continues to run at the maximum speed.

- It can be configured with 2-segment position table program supporting positioning/emergencystop/zero return and other functions, which can save the number of pulse output points of the host controller.

Electrical indicators

|

Model |

DE2205C |

DE2405C |

DE2608C |

|

Phase |

2 Phase |

2 Phase |

2 Phase |

|

Operating Voltage |

20V~50VDC |

20V~50VDC |

AC18V~80V DC36~110V |

|

Current range |

0~2A |

0~4A |

0~6A |

|

Subdivision settings |

The default value is 4000/rev,and the subdivision can be arbitrarily set in the range of 1-9999 |

||

|

Protective function |

Over voltage,over current,out of tolerance and overheating |

||

|

Parameter setting |

Number of subdivisions,signal valid edge,fault output signal level,position loop,etc. |

||

|

Motor encoder feedback |

AB differential input |

||

|

Use ambient temperature |

-20℃~80℃ |

||

|

Weight |

0.48kgs |

0.48kgs |

0.6kgs |

|

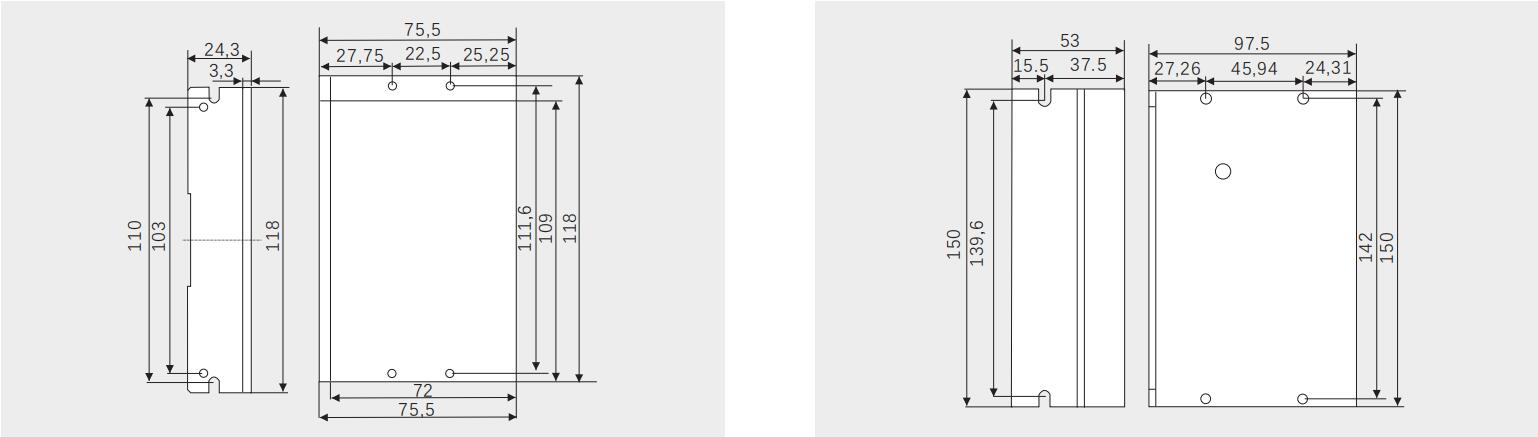

Dimensions |

118*24.3*75.5 mm³ |

118*24.3*75.5 mm 3 |

50*53*975mm³ |

|

Adapter motor frame |

28/36/42mm |

57/60mm |

57/60/86mm |

Installation dimension drawing

Itis compatible with pulse signal input and I/Ointernal control mode. One driveis with multiple functions bringing more expansion possibilities, greatly reducing system costs.

OBTAIN SAMPLES

Effective, safe and reliable. Our equipment guarantees the right solution for any requirement. Benefit from our industry

expertise and generate added value - every day.

1.png)